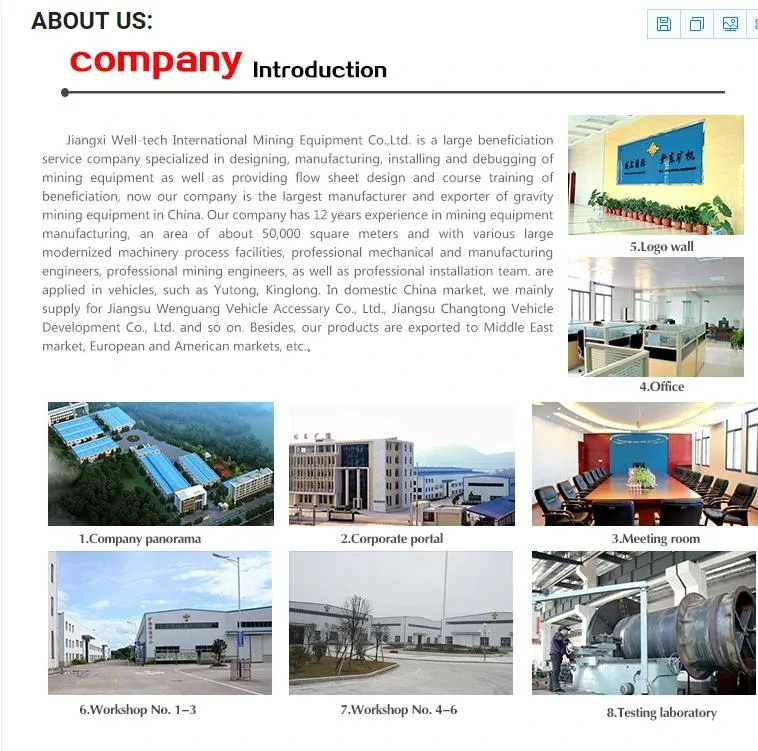

Jig Separation Machine for Manganese

Feature High capacity High concentration ratio and high recovery Fabricated with highest quality material Easy to instal

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | JT1-1/JT2-2/JT3-1/JT4-2/JT5-2 |

| Color | Blue |

| Customized | Non-Customized |

| Condition | New |

| After-sales Service | One Year for The Guarantee |

| Feeding Size | 6-30mm |

| Mining Object | Ore |

| Capacity | 1-15t/H |

| Wide Metals Application | Gold and Other Precious Metals Separator |

| Operation and Installation | Simple and Easy |

| Stable Operation Principle | Gravity Concentration Principle |

| Transport Package | Nude in Container |

| Specification | SGS, ISO9001: 2008 |

| Trademark | GANDONG |

| Origin | China |

| HS Code | 84741000 |

| Production Capacity | 2000/Year |

Product Description

FeatureHigh capacity

High concentration ratio and high recovery

Fabricated with highest quality material

Easy to install, operate and maintain

The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

Saving water 30-40% than ordinary jig

The pulsation speed very easy adjusted by regulator

Suitable for roughing and desliming

Can achieve a good result in processing such as placer gold, tungsten,iron, tin, hematite, copper, tantalum-niobium, titanium, manganese, barite, zirconium, chrome and gemstone etc.Our Saw-tooth Wave Ladder Jig is a new type of energy saving and high efficient gravity separation equipment and developed based on the traditional Sine Wave Jig. The difference between Saw-tooth Wave Ladder Jig and Sine Wave Jig is that the pulsation curve for jigging is saw-tooth wave shape, with speedy upward flow and slow downward flow. Bed layer is elevated integrally and slowly dropped with a long effective loose time, allowing significant increase of handling capacity for unit screen surface, decrease of lower limit of grain size recovery and large save of make-up water for undersize fraction. Industrial tests carried our of Saw-tooth Wave Ladder Jig and Sine Wave Jig for comparison showed that the recovery rate for operation of Saw-tooth Wave Ladder Jig is raised by Sn:3.01%, W:5.5%, Pb:1.63%, Zn:2.04%; The water consumption reduces 30%-40% than traditional Jig. The area reduces 1/3 and the stroke may adjust also.

| Model | Chamber | Feeding Size mm | Water added m3 /T | Pressure of water Mpa | Processing capacity t/h | Motor power kw | Dimension mm | Weight Kg | |

| shape | Area m2 | ||||||||

| JT0.57-1 | Ladder | 0.57 | < 6 | 1-3 | ≥ 0.5 | 1-2.5 | 1.5 | 1550× 780× 1530 | 610 |

| JT1-1 | Ladder | 1.04 | < 10 | 1-3 | 2-4 | 2.2 | 2270× 1110× 1890 | 900 | |

| JT2-2 | Rect | 2.28 | < 10 | 1-3 | 4-8 | 3 | 3225× 1550× 2050 | 1640 | |

| JT3-1 | Ladder | 3.3 | < 10 | 1-3 | ≥ 0.5 | 6-10 | 5.5 | 3180× 2000× 2600 | 3260 |

| JT5-2 | Ladder | 4.86 | < 10 | 1-3 | 10-15 | 7.5 | 3600× 2000× 2600 | 4500 | |

| JT1.5-2 | Rect | 1.53 | < 30 | 1-2 | ≥ 0.5 | 5-8 | 3 | 3200× 1550× 2050 | 1520 |

| JT4-2 | Rect | 4.33 | < 30 | 1-2 | 10-15 | 7.5 | 3600× 1850× 2600 | 4600 | |

Related Products